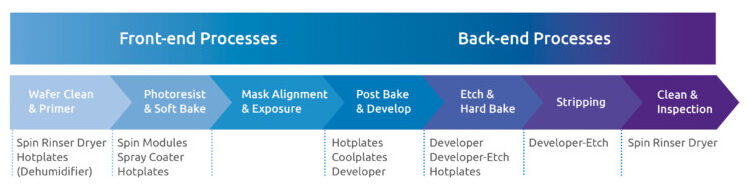

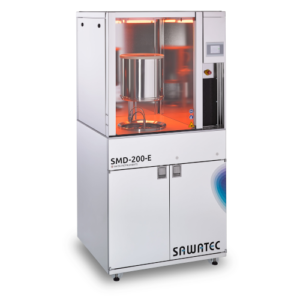

SAWATEC AG supplies various hotplates for typical soft bake and hard bake processes in lithography, MEMS and similar applications. The HP series is convincing due to its high level of uniformity and the high-precision process repeatability.

Outstanding features of the manual and semi-automatic hotplates are their robust design and ease of operation. The extensive HP series can be used for wafers from 150 mm up to 900 mm or 12×12 inch substrates.

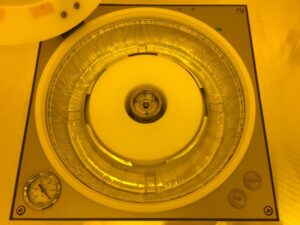

The hot-plate is covered with protection glass, which makes cleaning easier. Due to the high quality, robust design and easy handling, SAWATEC Hotplates are preferentially used in laboratories, R & D and small-scale production.

Hotplate HP-150

The temperature range of the Hotplate HP-150 is designed for up to 250°C. The set temperature and the temperature profile have narrow margins, meaning that a high coating quality can be achieved. It can be used for substrates with a diameter of up to 150 mm and thicknesses of 5 mm at maximum.

The hotplate is covered with safety glass, which makes cleaning easier. Due to the highquality and robust design and easy handling, SAWATEC hotplates are preferentially used for laboratories, R&D, pilot projects and institutes.

The high-precision, good value instruments are available both as portable bench-top and bench-mounted units.

FEATURES (BASIC CONFIGURATION)

- Temperature control with digital target and actual value display

- Automatic temperature limit switch, no overheating

- Hotplate with safety glass, easy cleaning

- Easy levelling of the hotplate, prevents discharge of photoresist

- Manual substrate fixation via vacuum

- Manual loading and unloading of the substrates

ADDITIONAL FUNCTIONS (OPTIONS)

- N2 flushing manually controlled, no oxidation

- Simple setup tool for optimal alignment of the hotplate

PERFORMANCE DATA

- Temperature range: ambient temperature up to 250°C

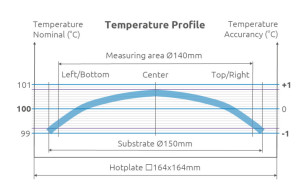

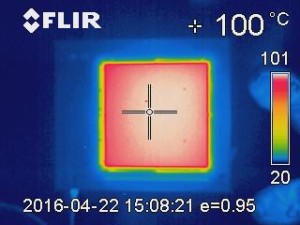

- Temperature accuracy: +/- 1°C at 100°C

For more details or the documentation please contact our Sales Team via contact form.

Offer/Documentation

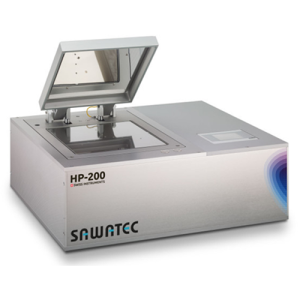

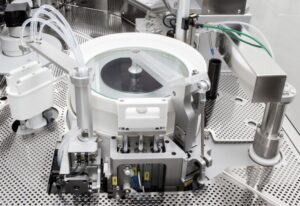

Hotplate HP-200

High precision soft and hard baking

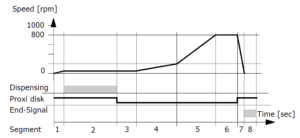

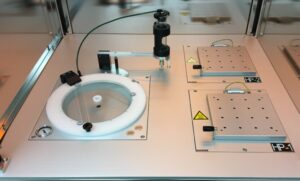

The Hotplate HP-200 was developed for precise soft bake and hard bake processes in lithography, in MEMS and similar applications. It can be used for substrates with a diameter of up to 200 mm and thicknesses of 14 mm at maximum (proximity/loading pins in the upper start position). The temperature range is designed for up to 250 °C by default. The set temperature and the temperature profile have narrow margins, meaning that a high coating quality can be achieved.

The high-precision instruments are available as mobile cabinet, portable bench-top and benchmounted unit.

FEATURES (BASIC CONFIGURATION)

- Temperature control with digital target and actual value display

- User-friendly process configuration with touch screen

- Quick start/stop function for repeat processes

- Automatic temperature limit switch, no overheating

- Heating ramp up possible with 24 program steps

- Proximity/loading pins, can be easily adapted to different substrate sizes

- Hot-plate with protection glass, easy cleaning

- Easy levelling of the hot-plate, prevents discharge of photoresist

- Manual substrate fixation via vacuum

- Manual loading and unloading of the substrates

ADDITIONAL FUNCTIONS (OPTIONS)

- N2 flushing program controlled, no oxidation

- HMDS priming program controlled, optimized adhesion

- Setup tool for optimal height adjustment of the pins and leveling of the Hotplate

PERFORMANCE DATA

- Temperature range: ambient temperature up to 250 °C

- Temperature accuracy: +/- 0.6 °C at 100 °C

- Electrical driven proximity and loading pins (stroke 8 mm)

- Program controlled adjustable proximity pins (0.1 mm increments)

- Pin-circle-diameters: 45 – 192 mm (2 – 8″)

For more details or the documentation please contact our Sales Team via contact form.

Offer/Documentation

Hotplate HP-200-Z

Ultra-high precision soft and hard baking

The Hotplate HP-200-Z was developed for ultra-high precise soft bake and hard bake processes in lithography, in MEMS and similar applications. The temperature range is designed for up to 300 °C by default. The set temperature and the temperature profile have narrow margins, meaning that a high coating quality can be achieved.

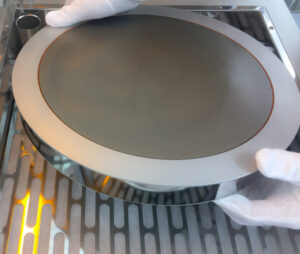

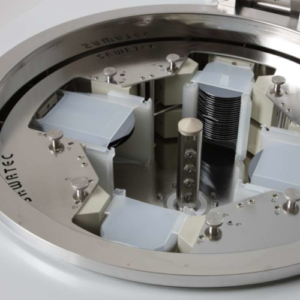

The HP series is convincing due to its high level of uniformity and the high-precision process repeatability. It can be used for substrates with a diameter of up to 200 mm and thicknesses of 14 mm at maximum.

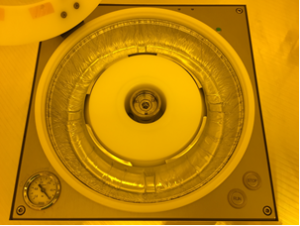

The multi-zone heating system ensures very high temperature distribution, which is adjustable for each zone. The hotplate also has a vacuum chamber and can be used as standard for bonding agent applications. The hotplate is covered with protection glass, which makes cleaning easier. Due to the high quality, robust design and easy handling, SAWATEC hotplates are preferentially used in laboratories, R & D and small-scale production.

The ultra-high precision instruments are available as mobile cabinet and bench-mounted unit.

FEATURES (BASIC CONFIGURATION)

- Temperature control with digital target and actual value display

- User-friendly process configuration with touch screen

- Quick start/stop function for repeat processes

- Automatic temperature limit switch, no overheating

- Heating ramp up possible with 24 program steps

- Free programmable heating curve with max. 10 °C/min

(25 – 300 °C)

- Free programmable cooling curve with max. 5 °C/min

(300 – 40 °C)

- Hotplate with multi-zone heating (9 zones) and with protection glass for easy cleaning

- Easy levelling of the hotplate, prevents discharge of photoresist

- Manual substrate fixation via vacuum

- Manual loading and unloading of substrates

- N2 flushing program controlled, no oxidation

- HMDS priming program controlled, optimized adhesion

ADDITIONAL FUNCTIONS

• Setup tool for optimal leveling of the Hotplate

- Temperature range: ambient temperature up to 300 °C

- Temperature accuracy: +/- 0.3 °C at 100 °C

For more details or the documentation please contact our Sales Team via contact form.

Offer/Documentation

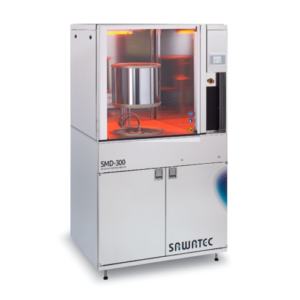

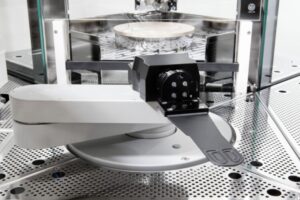

Hotplate HP-300

High precision soft and hard baking

The Hotplate HP-300 was developed for precise soft bake and hard bake processes in lithography, in MEMS and similar applications. It can be used for substrates with a diameter of up to 300 mm and thickness of 14 mm at maximum (proximity/loading pins in the upper start position). The temperature range is designed for up to 250 °C by default. The set temperature and the temperature profile have narrow margins, meaning that a high coating quality can be achieved.

The high-precision instruments are available as mobile cabinet and bench-mounted unit.

FEATURES (BASIC CONFIGURATION)

- Temperature control with digital target and actual value display

- User-friendly process configuration with touch screen

- Quick start/stop function for repeat processes

- Automatic temperature limit switch, no overheating

- Heating ramp up possible with 24 program steps

- Proximity as well as loading pins, can be easily adapted to different substrate sizes

- Hot-plate with protection glass, easy cleaning

- Easy levelling of the hot-plate, prevents discharge of photoresist

- Manual substrate fixation via vacuum

- Manual loading and unloading of the substrates

ADDITIONAL FUNCTIONS (OPTIONS)

- N2 flushing program controlled, no oxidation

- HMDS priming program controlled, optimized adhesion

- Setup tool for optimal height adjustment of the pins and leveling of the Hotplate

PERFORMANCE DATA

- Temperature range: ambient temperature up to 250 °C

- Temperature accuracy: +/- 0.8 °C at 100 °C

- Electrical driven proximity and loading pins (stroke 8 mm)

- Program controlled adjustable proximity pins (0.1 mm increments)

- Pin-circle-diameters: 45 – 292 mm (2 – 12″)

For more details or the documentation please contact our Sales Team via contact form.

Offer/Documentation

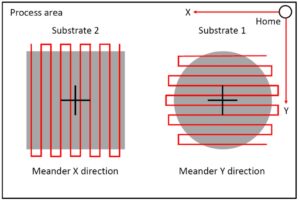

Hotplate HP-600

The temperature range of the Hotplate HP-600 is designed for up to 200°C. The set temperature and the temperature profile have narrow margins, meaning that a high coating quality can be achieved. It can be used for substrates with sizes of 200 x 200 mm up to 600 x 600 mm, round or square.

The hotplate is covered with safety glass, which makes cleaning easier. Due to the high quality and robust design and easy handling, SAWATEC hotplates are preferentially used for laboratories, R&D, pilot projects and institutes.

The high-precision Hotplate HP-300 is available as a mobile cabinet.

FEATURES (BASIC CONFIGURATION)

- Temperature control with digital target and actual value display

- Quick start/stop function for repeat processes

- Automatic temperature limit switch, no overheating

- Heating ramp up possible with 24 program-steps

- Proximity as well as loading pins

- Hotplate with safety glass, easy cleaning

- User-friendly process configuration with touch screen panel

- Manual substrate fixation via vacuum

- Manual loading and unloading of the substrates

ADDITIONAL FUNCTIONS (OPTIONS)

- Simple setup tool for optimal alignment of the hotplate

PERFORMANCE DATA

- Temperature range: ambient temperature up to 200°C

- Temperature accuracy: +/- 1.5°C at 100°C

- Electrical driven proximity and loading pins

- Substrate with a weight of max. 10 kg can be processed

For more details or the documentation please contact our Sales Team via contact form.

Offer/Documentation